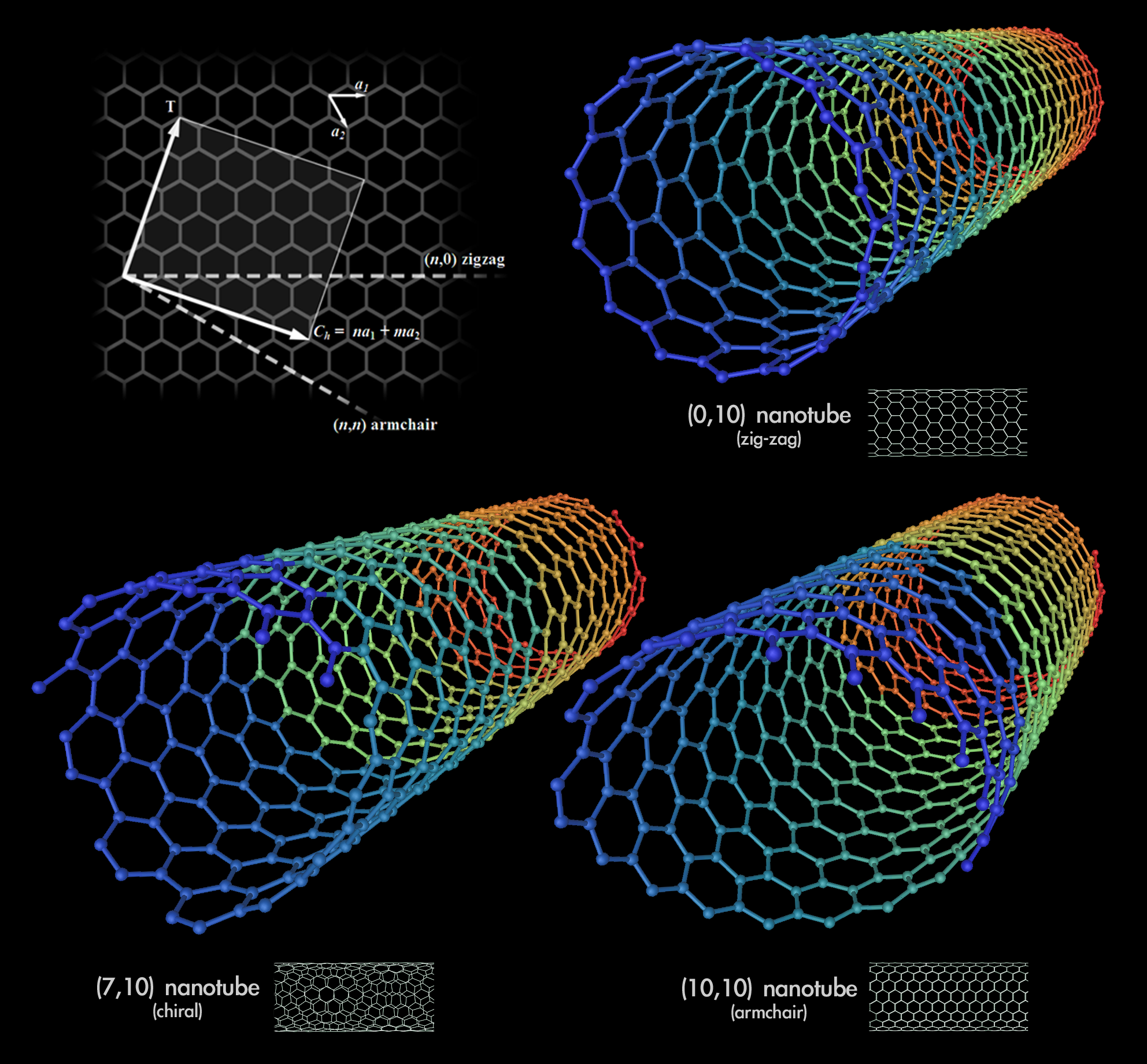

SAN DIEGO, CA – A new study from the University of California, San Diego explores how carbon nanotube (CNT)-reinforced steel can address climate and engineering challenges. Steel production accounts for approximately 7% of global carbon dioxide (CO2) emissions, according to the International Energy Agency. By integrating CNTs, researchers aim to create stronger, lighter materials that reduce the need for steel production, thereby lowering emissions.

The study highlights the extraordinary properties of CNTs, such as tensile strengths of 100–200 GPa (compared to steel’s 350 MPa) and high thermal conductivity. These properties make CNT-reinforced steel ideal for applications like fusion reactors, space missions, and lightweight transportation systems. The research, detailed in a paper by Reza Rahemi, emphasizes material efficiency as a key strategy for decarbonization, potentially reducing CO2 emissions by up to 30% as projected by International Energy Agency (IEA) as well.

“CNTs can revolutionize steel by filling microstructural gaps, enhancing corrosion resistance, and improving strength-to-weight ratios,” Reza Rahemi said. “This could significantly cut emissions in industries like aviation and construction.”

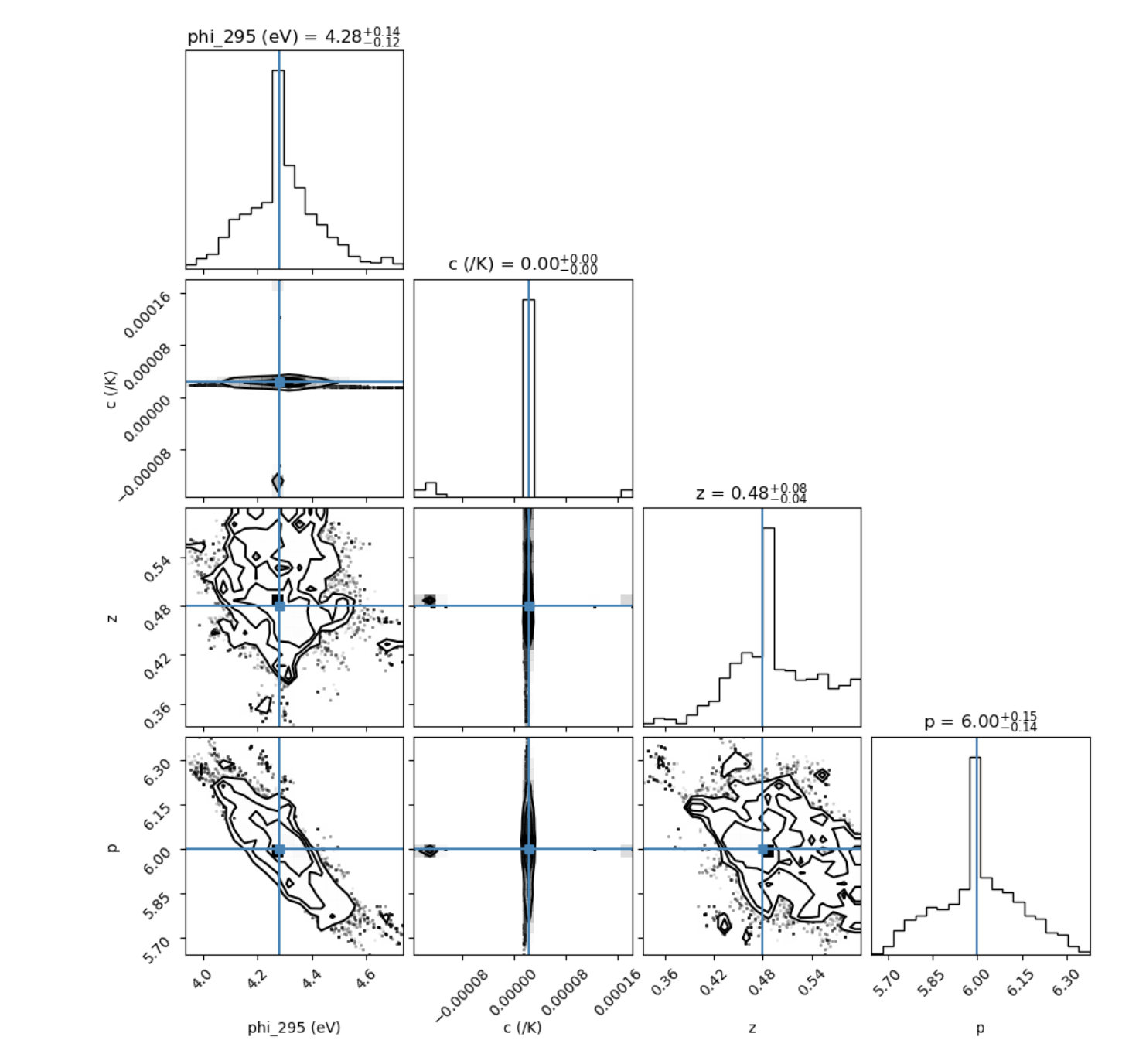

The study also explores computational approaches, such as Monte Carlo Markov Chain (MCMC) simulations and Bayesian models, to optimize material properties. These methods, applied to models like the Rahemi-Hua equation, help tailor steel for high-energy applications, reducing trial-and-error in material design.

CNT-reinforced steel, produced via techniques like laser powder bed fusion shows promise for high-temperature applications. However, challenges remain, including high production costs and technical difficulties in integrating CNTs into steel matrices. Corrosion resistance, improved by CNTs bridging microcracks, could reduce the 5–10% of global CO2 emissions linked to replacing corroded steel.

The research aligns with global efforts to innovate in steel production, particularly in Asia, the dominant player in steel supply. Advanced manufacturing techniques, like additive manufacturing with CNTs, could further reduce carbon footprints while enabling robust, lightweight materials for sustainable urban infrastructure and transportation.

As climate challenges intensify, integrating CNTs into steel offers a path to mitigate emissions and enhance material performance. The UC San Diego team continues to collaborate internationally to refine these technologies and address the evolving needs of a warming planet.